To improve inventory turnover we need to increase the efficiency of a business to turn stock into sales. For any business in any industry, the faster it turns inventory into sales, the better it works. However, in practice, businesses need to cater to many factors that affect inventory management. Each business sector and industry set standards for inventory turnover or business operational efficiency.

How to Calculate Inventory Turnover?

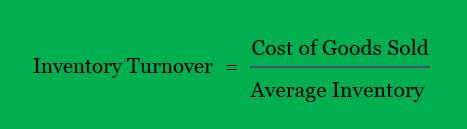

Inventory turnover can be calculated in different ways. The standard form of calculating the inventory turnover is to analyze the cost of goods sold and average inventory in stock.

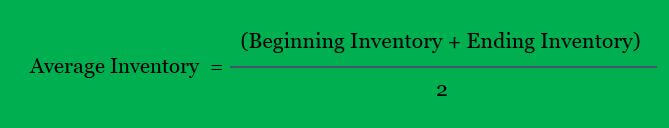

Where the average inventory is calculated by using the formula below:

Some businesses may use the revenue or Sales figure instead of the Cost of Goods Sold.

Example

If a company ABC has an annual revenue of $10 million with a COGS figure of $ 7 million and an average inventory of $ 1.5 million. Its Inventory turnover will be:

Inventory Turnover = 10 / 1.5 = 6.6 time by sales. Or

Inventory Turnover = 7 / 1.5 = 4.6 time by COGS

The cost of Goods sold offers a realistic and efficient metric than sales figures. Businesses should use COGS figures wherever possible.

Why is it Important to Improve Inventory Turnover?

If you breakdown the inventory turnover into components of the business, its importance will reveal as a critical business efficiency metric. Inventory management involves multifaceted business strategies including supplier relations, supply chain and transportation, stock management, operational efficiency, labor management, and sales and marketing. If the business manages a good turnover of inventory, it indicates overall good business health.

Inventory turnover improvement can bring manifold benefits to any business:

- Improved inventory turnover increases the operational efficiency of the business

- To improve the inventory turnover, it improves the cash and liquidity position for the business

- It improves the working capital management of the business with better management of current liabilities such as short-term debts

- It improves supply chain management, supplier relations, and customer relations

- Investors are keener to observe the efficient ratios before investing in a business

- Creditors and banks also closely observe the efficiency ratios like inventory turnover

- Effective inventory turnover reduces costs

Working capital management and short-term financing are also closely linked with inventory turnover. Often businesses’ cost of borrowing increases due to lower cash reserves.

Achieving improved inventory turnover is often challenging for many businesses. For retailers and wholesale dealing companies it may not pose extreme difficulties but for manufacturers, the inventory turnover can even lead to business failure risks.

How to Improve Inventory Turnover?

The first step in improving an inventory turnover for any business should be to conduct an in-depth inventory audit. From the outset, there are only two components which make for the inventory turnover, COGS, and average inventory. However, the business will have to dig deeper to find the causes affecting inventory turnover. It can be achieved by improving both equation components coherently.

Perform an Inventory Audit

Performing an inventory should be the first step in improving inventory management for any size of business. Inventory audits can reveal the current stockpiles, accuracy of records, supplier relations, and minimum order quantity levels. Without a clear assessment of the current position, it would be impossible for the business to manage the inventory turnover. An inventory audit may also reveal any inefficiencies or lack of operational capacity for the business.

Introduce Inventory Management Automation

If your business hasn’t yet adopted inventory automation, it’s time to move from the traditional pen-and-paper working to inventory automation. Automation of inventory management will save time and costs in the long run. It can bring management benefits for in-time supplies and increased data analyses.

Supplier Relations and Transportation

Reliable suppliers play an integral part in providing timely raw material supplies. Often businesses need to import key product components. Managing supplier relations effectively can reduce the waiting time for raw inventory substantially. For businesses with large volume and size raw material needs, logistics and transportation also play a key role in inventory management. One way of improving logistics is to outsource the raw material and finished goods transportation to specialists.

Improved Forecasting

Inventory automation and improved supplier relations will undeniably lead your business to more accurate inventory forecasting. Often businesses complicate inventory forecasting due to a lack of analytical data. Different product inventory needs may require separate inventory scheduling. An improved forecasting plan can substantially improve the inventory lead time.

Inventory forecasting is also directly related to product demand forecasting. The business should carefully follow the seasonal and market trends. Seasonal demands, economic downturns, and other significant events may change the product demands and affect the product inventory levels.

Increasing Operational Efficiency and Capacity

This is where the business can manage its cost of goods sold. Raw material prices can be reduced with bulk buys and discounts from suppliers. Factory overheads and indirect costs also add up for a significant portion of the total product cost. Increasing production capacity and higher production efficiency can reduce the cost of goods sold and increase inventory turnover.

Higher production capacity and improved operational efficiency will also increase the sales and hence liquidity of the business.

Removing Operational Waste and Idle Time

Manufacturing businesses in particular need to adapt to a continuous improvement technique. Removing operational inefficiencies and reducing operational waste can lead to increased operational output. One hurdle businesses face is the labor and machine idle time that can be reduced with better raw material supplies and improved machinery.

Offer Incentives to Customers

Finished goods and lower sales can also reduce inventory turnover. The ending inventory also plays an important role in managing the turnover. One tried and tested method of improving finished inventory levels is to offer bulk buy and discount incentives to your customers. Although wholesale customers may demand deeper price discounts and extended payment terms.

Managing Reorder Stock Point

You can easily manage the reorder stock point with automation. Businesses need to set aside the safety or emergency stocks and assess the reorder quantity accurately and timely. For large manufacturing facilities with multiple products, the reorder points can significantly create hurdles in improving inventory turnover to finished goods. If managed properly, it can reduce the operational idle time.

Continuous Audit and Improvement

Much like the business continuous improvement philosophy of Total Quality Management (TQM) or Just-in-Time (JIT), inventory management needs continuous management. Businesses can adapt to cyclic auditing and physical inventory controls to improve inventory management.

Important Considerations

Businesses opt between inventory management methods of FIFO, LIFO, or JIT when faced with inventory management troubles. It’s important to choose the right inventory management method, but that makes for only one part of the total inventory management. Inventory turnover can best be increased by increasing operational efficiency and reducing supply chain frictions. Turning raw material into cash sales takes a complete business management philosophy rather than just calculations.